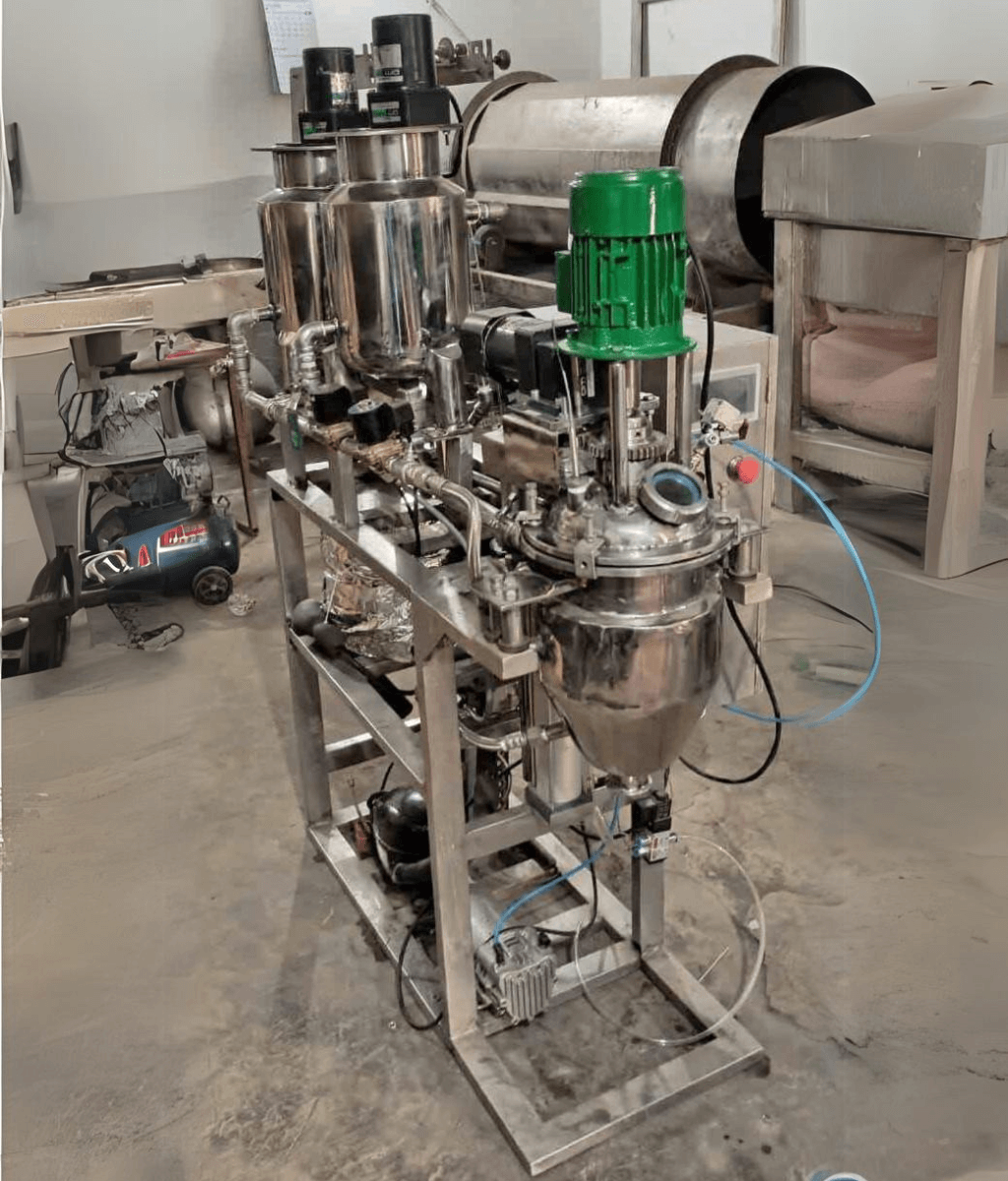

Vacuum Cream Mixer Description:

Functionality:

- Vacuum Mixing: This mixer operates under a vacuum, removing air bubbles and reducing the chances of oxidation during the mixing process. This ensures a more stable and homogenous product with an extended shelf life.

- Homogenization: It is equipped with high-shear mixing blades or homogenizers that break down particles and ensure even distribution of ingredients, resulting in a smooth, consistent product texture.

- Heating/Cooling: The mixer may also be fitted with a jacketed vessel for precise temperature control, allowing for both heating and cooling processes. This is essential for materials that require specific temperatures for proper mixing or setting.

- Automated Controls: Modern vacuum cream mixers often come with programmable logic controllers (PLCs) for automated operation, allowing for consistent and repeatable production cycles.

Applications:

- Cosmetic Industry: Used to produce creams, lotions, ointments, gels, and other skincare products that require uniformity and smooth textures.

- Pharmaceutical Industry: Utilized for mixing medicinal creams, ointments, and gels, ensuring the even distribution of active ingredients.

- Food Industry: Can be used to create emulsified food products like mayonnaise, sauces, and dressings, ensuring a consistent texture and flavor.

Technical Specifications (may vary based on model):

- Capacity: Ranges from small-scale lab mixers to large industrial units capable of handling several hundred liters.

- Power: Driven by powerful motors, often equipped with variable speed controls for different mixing intensities.

- Materials: Constructed from stainless steel to ensure hygiene and durability, with polished surfaces to prevent contamination.

Benefits:

- High Efficiency: Capable of producing high-quality products quickly and consistently, reducing production times.

- Versatility: Suitable for a wide range of viscosities and formulations, making it adaptable to different product types.

- Improved Product Quality: Ensures thorough mixing without the incorporation of air, resulting in a better end product.

This equipment is essential for any manufacturer aiming to produce high-quality creams and emulsions on an industrial scale.

Reviews

There are no reviews yet.